Metal Frame Attachment Information

Metal Rollform

Purpose: This attachment is welded to the metal frame and retains the plastic extrusion. Universal design accommodates tubing dimensions of .75″ to 1.5″ O.D.

Standard length – 24″

Part number – DA-24

Plastic Extrusion

Purpose: The Dymetrol® suspension is sewn to the extrusion and is in turn clipped onto the rollform.

Standard length – 24″

Part number – DA-24

Attachment Procedures

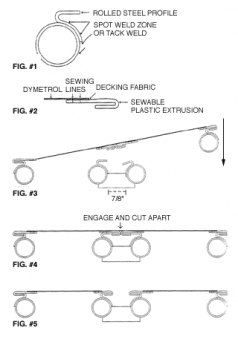

Spot weld or tack the rollform to the outside radius seat frame – Figure 1.

Use a high quality bonded nylon thread (threads USA, 69 Twistlon Plus or equivalent) to sew the Dymetrol suspension separated by 3/4″ wide strips of decking type of material to the plastic extrusion using a double sew line. Machine setting should allow for 7-8 stitches per inch – Figure 2.

Prestraining the Dymetrol® or Entransit is accomplished by Book Stretching (two or more seats per application). All grades of Dymetrol must be prestrained a minimum of 5%. Entransit must be prestrained a minimum of 7% Determine Dymetrol® width and extrusion placement – Figure 3.

Attach outer extrusions to the outboard rollforms. Using the frames themselves, separated by a spacer cam in place – Figure 4.

Depress the inclined frame stretching the fabric and aligning the extrusions adjacent to the inboard rollform. Cutting the fabric between the extrusions will engage the extrusions onto the rollform.