Dymetrol® seating support systems are available in several grades ranging from soft to extra firm.

Below is a table of the physical properties of sateen weave fabrics.

| Soft (C100S) | Med (C125S) | Firm (C150S) | X-Firm (C200S) | |

|---|---|---|---|---|

| Warp Ends/in. | 100 | 100 | 100 | 100 |

| Warp Tensile, lb./in Minimum | 350 | 350 | 350 | 350 |

| Fill Yarn Diameter, Mils. | 14 | 14 | 14 | 14 |

| Pick/in. | 14 | 17 | 21 | 26 |

| Filling Tensile, lb./in. Minimum | 50 | 60 | 80 | 100 |

| Filling Elongation at Break, % Minimum | 50 | 50 | 50 | 50 |

| Spring Rate, lbs./% strain/in. width | 1.0 | 1.25 | 1.5 | 2.0 |

| Weight, Oz./Sq. Yd. | 8.0 | 8.7 | 9.3 | 10.3 |

Note: Physical constants are averages and may vary ± 5% of values shown.

Performance Properties—Sateen Weave Fabrics

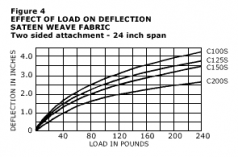

- Load Elongation Curves (Figure 1)

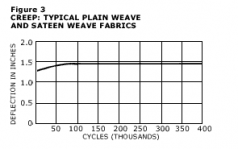

- Force Deflection, Sitting Cycle (Figure 2)

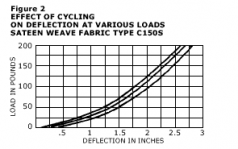

- Creep: 4% average (Figure 3)

- Durability – BIFMA Testing: Passed BIFMA cycling and drop test, ANSI/BIFMA X5.1.

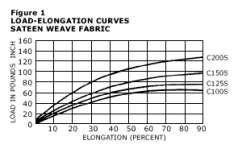

- Load vs. Deflection (Figure 4)

- Ozone Resistance: Not affected by ozone.

- UV Resistance: Not intended for direct exposure to sunlight.

- Fungus/Mildew/Urine: Not affected by mildew, fungus, bacterial attack or urine.

- Gasoline, Salt Water, Acetic Acid (.1 Normal), Artificial Sweat, Sodium Hydroxide (.1 Normal): Not affected.

- Organic Solvents: Certain solvents should be avoided such as Methylene Chloride, Methethyl Ketone and Perchloroethylene.

- Flammability: The sateen weave fabric (untreated) has passed the UFAC test (fabric classification test method, August, 1982) Class 1, and NFPA 260A, Class 1, and the California Bureau of Home Furnishing Test (technical bulletin #117, dated January, 1980).

Flame-retardant treated sateen weave fabrics are currently available.